Have a story idea

Have a story idea? Send it to us here.

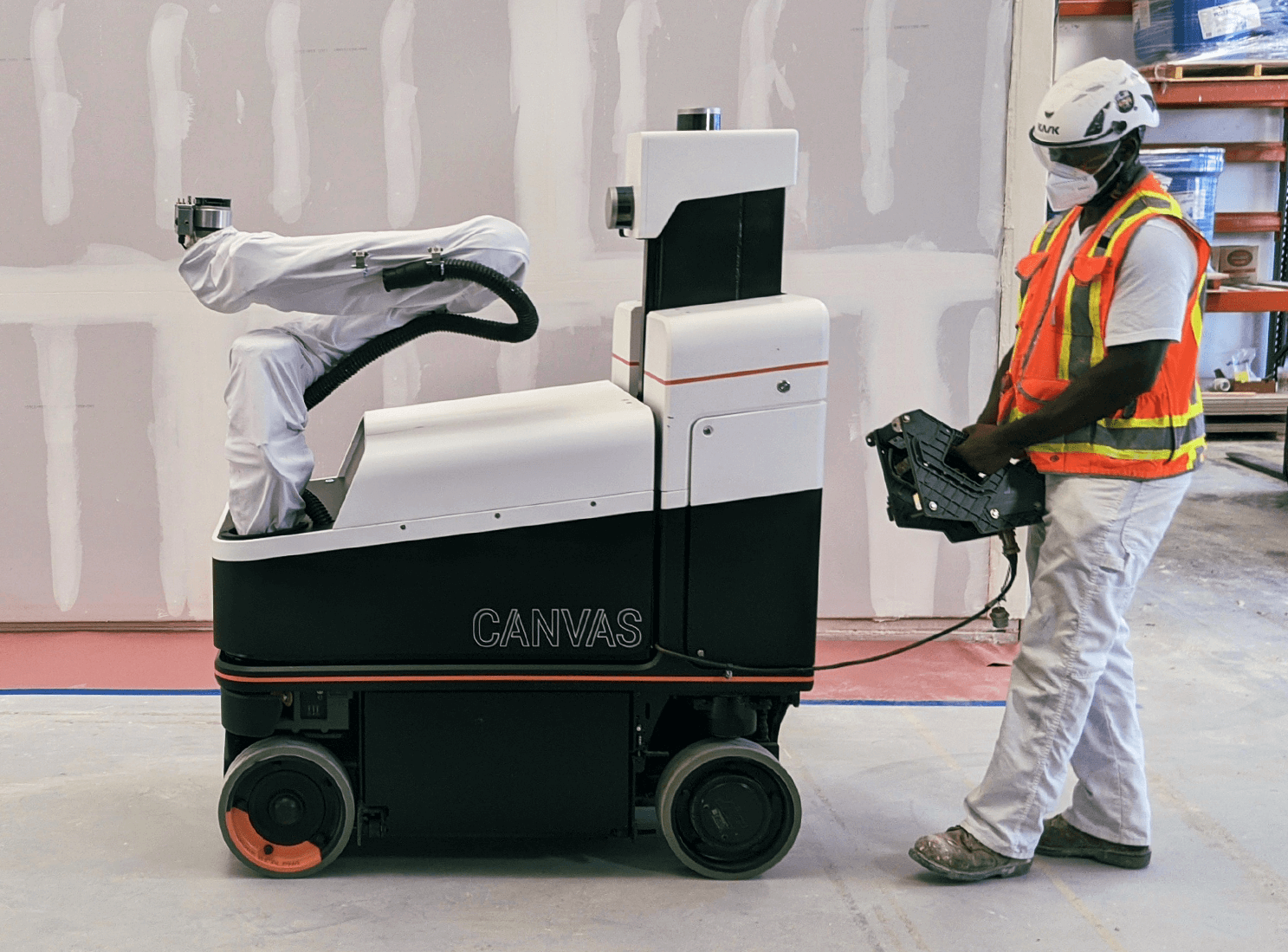

Source : Canvas

July 1, 2022

Author : Pratigya Dhali

The construction industry is widely known as a labor-intensive industry, often slow to adapt to technological advancements.

According to reports, however, 55% of construction companies across the US, Europe, and China use robotics. Though this lags behind the 84% of automotive companies that use robotics and 79% of manufacturing companies.

On the horizon though are a variety of advancements that may lead to even more robot-powered job sites.

Finishing drywall is one of the most physically demanding of jobs. For the installation and finishing of drywall, specialized workers are required. However, a good deal of that effort consists of repetitive sanding and finishing. Can robot helpers come in to plug this gap and reduce the load of repetitive work?

Canvas, the construction robotics company, recently launched its innovative Level 4 Targeted Spray system. The robot can complete large sections of drywall semi-autonomously.

“The robot focuses on broad spaces, high-volume sections, as well as hard-to-reach areas like high spaces and corners,” explains Kevin Albert, CEO, and co-founder of Canvas. “The machine can handle the application of the finishing compound and the sanding of it. Workers do the taping and handle the more complex geometries.”

In a period of severe labor shortages, record building demand, and at-risk construction costs, Level 4 Targeted Spray (L4TS) was developed based on input from valuable stakeholders. It makes drywall finishing safer and more predictable.

The robot arm can operate at heights of up to 17 feet, thanks to a telescoping mast. Canvas' L4TS has been calibrated to give a near-perfect or level-5 finish. The Level 5 finish is the highest grading on the Gypsum Association's scale. To be eligible for a level-5 finish, the drywall needs a thin skim coat of finishing compound throughout the surface for a uniform appearance.

Todd Mercer, vice president of strategic innovation at Webcor, asserts that the quality of the work produced by the Canvas robot has surpassed expectations, even while human workers return to do any necessary finishing touches. He explained, “We can deliver at a higher level of quality now at the same cost, and as the product continues to evolve, the narrative may soon be the same quality at less cost.”

The Canvas robot is made to start working quickly, unlike other construction robots that need pre-loaded designs or programming expertise to set up and get started. The robot uses onboard optical sensors to recognize the work area before carrying out the tasks given to it by the operator. A vision and laser scanning system help comprehend the geometry of the building and its interior.

The employee using a tablet can track the machine’s operation and give it specific instructions, including where to spray and where not to, as well as how to adjust the thickness.

Altogether the machine can reduce the cycle time for a Level 5 finish by 34%, while achieving 99.9% dust recapture.

The Canvas System is a versatile method for finishing drywall and offers exceptional scheduling flexibility by cutting conventional finishing timeframes from seven to two days.

In recent years, there has been a persistent problem with a lack of workers in the construction sector, particularly in skilled professions like interior finishing. The use of robotic drywalling is thus a force multiplier.

According to Chen Feng, an assistant professor at New York University’s Tandon School of Engineering, robots can boost worker safety. The physical demands of hard labor could be reduced or eliminated by the robots. Overall, hanging drywall is very taxing and can lead to back, arm, and shoulder injuries, and this has been successfully mitigated with Canvas’ robots.

Through their Innovation Partner Program, Canvas is currently teaching staff members at a few chosen contractors how to utilize the robot. Seven large drywall and self-performing contractors are already training their personnel to use the robot and considering how it might alter the way they set up their crews. The contractors already using the device include Webcor, DPR Construction, Swinerton, Nevell Group Inc., KHS&S, Daley’s cDrywall & Taping, Inc., and California Drywall.

Keep following Contractor News for the latest on technological developments in construction.

Category : Market Watch Mobile Technology Tech